With the wind noise test branches/blowing nozzle test benches developed and patented by us, inner sounds in the vehicle are localised. This way, leaks from production or mounting errors at critical points such as window, door and roof seals, as well as at the mirror triangle, can be located simply and quickly with an acoustic evaluation system. Wind noise test benches for the automotive industry are an important indicator for your quality assurance and reliably prevent unnecessary customer complaints and the connected elaborate troubleshooting and rework in the service workshop.

Customer requirements regarding inner noise are high, specifically for high-quality vehicles. Wind noise test benches therefore are also used in the development area and save cost-intensive examinations in the wind tunnel.

Vehicle manufacturers such as Porsche, Ferrari, Mercedes use our wind noise test benches in the end-of-line area as well. Here, they can test all critical items of the vehicle within the required cycle time. The results of the measurements are reviewed based on a manufacturer-specific tolerance band and submitted to the superordinate control system vehicle-specifically on demand. The test is objective, reproducible, and will also verifiably recognise all NOK vehicles that have been subjectively assessed as NOK during the conventional road drive by the worker. Road drives with new vehicles to recognise sealing problems - with disadvantages such as time expenditure, costs, damage, weather influence, subjectivity - thus can be dispensed with entirely.

How does a wind noise test bench work?

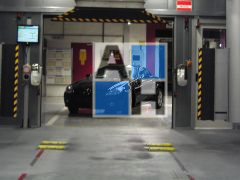

The vehicle to be tested is taken to a sound-insulated test bench cabin specifically designed for this application by a conveyor belt or with its engine.

A moving portal with nozzles then moves specifically to the critical points where undesired air stream noise may arise. The speed of the air escaping at the nozzles can be gradually set according to a previously specified range.

An acoustic measurement is performed in the customer's specified test position; the measurement is evaluated within a tolerance band and the vehicle is classified as OK or NOK.